Going back to university for classes, you are quickly overwhelmed with why you wanted to leave this dump and never come back. Between the headaches of coursework, the pain in the ass that is professors who still think the War was relevant to your field even though you'd clearly surpassed it, and the armchair designers, you were ready to pull your hair out. Thank God for your wife and her patience, as well as your wonderful daughter. Without the two of them, you'd go mad here.

Still, between the alcohol, fighting with professors, joining the student unions, and a few choice words you had for the other grad students, things went along fairly well. With the company paying you to go to school, the first two years sped by fairly easily, and the boring and practical classes fell away like chaff before the thresher. This didn't get you out of everything, though: far from it!

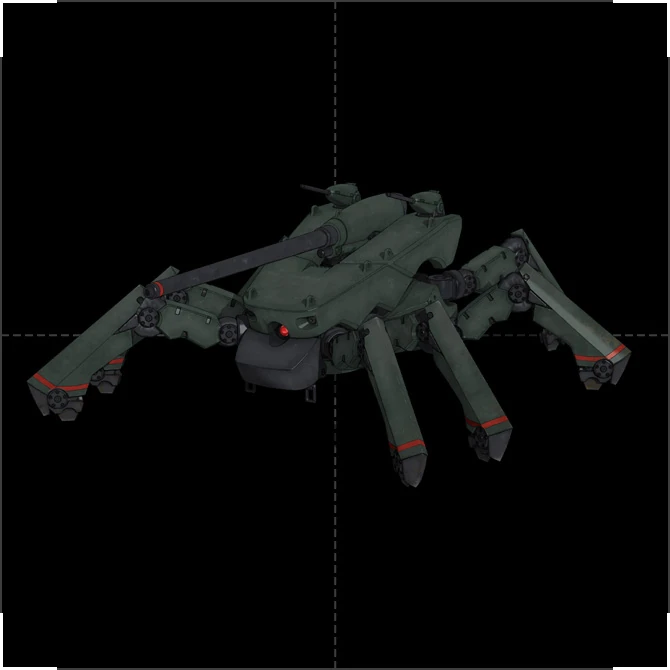

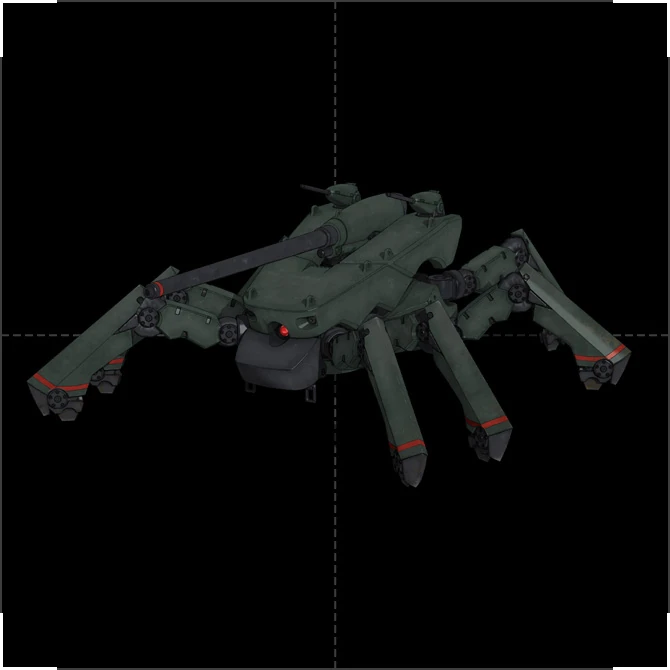

It was the start of your third year that you actually got to get to work setting up for your thesis project: a hexapodal mecha capable of doing… well, something new. New was good, but really, nobody had really pushed the boundaries in hexapodal mecha since bipedal mecha got in big. You understood why, but the logic was still ugly.

There were two main advantages to hexapodal mecha: increased stability, and increased weight/pressure clearances. Both took more than a little explaining.

It was a fact of life that speed and stability were inverse factors. The first French mecha had been hexapodal out of necessity: early 0.5krpm and 1k rpm gyroscopic stabilization units didn't have the rotational inertia to enable the mecha to recover from off-center loading. However, on a hexapod, that low stabilization wasn't a serious issue: the gait and walk cycle could ensure there were always enough feet on the ground to keep the mecha properly rooted. However, this had made the mecha slow: engines weren't powerful enough to keep all six legs powered all the time, so there was an inherent input lag as the transmission powered the leg, which enabled initial positioning, followed by the thrust cycle, and then depowering of the leg. Compared to a bipedal mecha, which could dump more power per leg and had a far cleaner walk cycle since it could remain under constant engine power loading, it was incredibly inefficient. Bipedal mecha could walk and trot faster than hexapodal and quadrupedal mecha, and some brave pilots in racing mecha could even break into a fully suspended run in the straights. Bipedal mecha, depending on configuration, could also take up a canter instead of the walk and trot. The hexapod, though, was cripled by complexity: it could only walk, and your development of a system that could commit to a trot in the Fourmi was already revolutionary.

By the by, you were quite amazed some mad lads had managed to pull that off, but since it took extensive cockpit remodeling and a very clean walk cycle cylinder (as in one cleaned of input control data) it would never be a common maneuver.

The second important factor of hexapodal mecha was their ability to handle utterly ridiculously massive amounts of weight. Reducing ground pressure was always the deal Faust made in this business, for it was ground pressure that determined the maximum weight of mecha and the resultant designs. With the criminally early initial foot designs and the brutally unforgiving conditions of the Front on which they were used, a bipedal system would be unable to hold a respectable engine and firepower, much less be able to armor them both. However, by increasing foot area by increasing feet, the problem was solved. These days had seen their fortunes reverse, though: with the innovation of the twenty- and twenty-five ton paired feet, a bipedal mecha could hold the veritable Araignée up on two legs instead of six in good terrain.

In short, your decision to thereby focus on hexapodal mecha was seen as a bit of a laughingstock. An old man grasping at straws, trying to bring back the Old Days. While you might not have wanted to remind them you had less than a decade on them, it might not stick well and putting on airs of l'Ancien Régime was good for a laugh every once and a while. More importantly, you knew the pool wasn't tapped out for this design choice yet.

Designing your mecha, you had four simple goals in mind.

One: Design a product that could do something categorically impossible for a lighter mecha of 25 tons. Since you could load up to 75 tons on your current maximum weight feet and actuators, this left a lot of ideas open.

Two: Sell this mecha to a company so you got full license rights. This was far more lucrative than your standard salary, and would be a very powerful tool to gain freedom at Hotchkiss.

Three: Create this mecha with as many off the shelf parts as possible. There was no Hotchkiss Foundries backing you up, and even though they were paying for your work, that didn't mean they were bankrolling your parts prototyping. Everything that wasn't in use by someone else would be a fight to get built- so outsource everything.

Four: Design a mecha that was as safe for the operating crew as possible. You still felt a twinge of guilt over the death of the test driver of the Cavalry Mecha, now named le Coq in service, and wanted to prevent that, as well as to ensure maximum crew safety in service.

Now, from these four requirements, some ancillary details crept out of the woodwork. This would obviously have to be a combat mecha, or a mecha that could be refitted to a combat mecha. Fortunately, you knew that after some exercises recently, the Mecha Branch had been having absolute conniption fits over their supplies of infantry mecha. The Araignée's massive, expansive, expensive mid-life overhaul hadn't managed to change the fact it was a thirty-five tonner armed with old weapons and older armor. In exercises, the Renault design- jokingly referred to as 'Quasimodo'- would, could, and did fuffil every mission better than it's well-tuned cousin.

Therefore, this would be an infantry mecha- but speed was no longer something an infantry mecha could abandon. Likewise, it still needed a shell-firing gun, even if you were mentally dreading any thought of cramming in the mle. 1897/14 again. Machine gun blisters might be worth looking into, or some other close-in weapons system to prevent envelopment. Good armor, too.

Of course, while you were wishing for this, you might as well wish someone would find that mythical sword in the stone and pull it out to become a good King of England- or at least remove the stick from their asses.

Practically, you had more pressing problems to fix. In order to develop more speed, you'd need either ruinously large pools of horsepower, or a way to adjust your gait somehow to move past the trot that had been the bat to the kneecaps on your plans. Fortunately, you had the power of the Christy Joints System on your side…

…and more importantly, absinthe. The Christie System, an amazing vertical actuation system to help mecha operate in any circumstances and the first true floating hip, was thrice-useless on a hexapod because the loading angles were different and power wasn't actuated on the main load axis. However! You were the best mecha designer in France! And drunk! Very drunk!

When you sobered up, you had a messy, if readable, diagram of how to mate the Christie system to the hexapod. The key element was redirecting thrust.

What made the Christie system so well-suited to bipeds was the fact that a bipedal hip was one axis of motion for the final drive. What the Christie did, mechanically, was add a second axis of motion, in allowing the entire leg to cant inboard or outboard slightly relative to the other leg, taking strain out of the ankles and knees as well as adjusting the ammount of flex in the knee. However, a hexapodal hip was two axises of movement: the up-down one, and the fore-aft one.

Therefore, drunk-you had decided, the correct solution was to flip the bloody thing flat on it's side, and transmit power from the transmission to a decoupled tensioner that rested in the hip and was powered off a helical bevel gear, with a top-end corrector to reposition things as per the adjusted master cylinder output when the leg was out of battery on a return stroke instead of a driving stroke. A de-tensioning piston would handle the cable reel to unpower the knee when need be, and then, as the piece-de-resistance, this would all be held on an overhead mount, with a shaft running through this mess to actually power the hip, using yet more helical bevel gears as part of the prime moving system.

In defense of your drunken self, helical bevel gears were cool.

Either way, you had the beginnings of a hip module. Now, the question was 'everything else'.

////

VOTES

Go Fast

[] You will hit speed targets by including enough horsepower to tow a battleship. Either a new engine, or two old engines, or something. You'll figure it out: this is an arch-prototype for a reason.

[] The main issue with speed is walk cycles: therefore, you will re-engineer the master cylinder so you can actually get this thing up to a proper trot, or perhaps even a canter.

[] Why not both? Two engines and a sufficiently well-designed transmission should let you bypass most of the most odiferous requirements in power-cycling, if you ensured each engine ran a different bank of legs.

Bigger is Better

[] If you're conservative with 20-ton bearing feet, you can probably work your way into a solid 60-ton mecha: a massive improvement over the old spiders.

[] There are new, if slightly touchy, 25-ton bearing feet out on the market, thereby granting you a mecha of 75 tons maximum and the ability to win a towing or ramming contest with the British monstrosities.

[] You've heard of a new, radical group of students that believe they've cracked the pascal delta with a powered articulation foot, allowing them to build a 30-ton foot. This in turn means a 90-ton mecha, and frankly speaking if you can make a 90 ton mecha make more that forty kilometers per hour then you can attack and dethrone God with it.

86-eighty-six.fandom.com